Toolshop

With almost 25 years of experience in tool construction and production, we offer our customers both new tools and tool transfer projects. On-site injection molding, our team of skilled operators is ready to maintain tools with costefficiency, while also producing up to 50 projects/tools per year.

Construction and production

Up to 50 tools per year

Skilled operators

Cost-efficient

Our services and technology include conventional tuning and milling; Novapax polishing system; tool construction and parts simulation; rapid prototyping (powder/PE electrodes); 3D solid modelling; HURCO pocessing centre; Charmilles CNC erosimate.

Injection moulding

Our founding sector is where we are most experienced. With over 50 years of working in the field, we focus on producing high quality parts and using the best materials. With Plamingo, you would quickly find reliability and flexibility, coupled with our honest integrity, to be our signature quality.

Over 50 years of experience

High-quality parts and materials

Realiability and flexibility

Value-added services

Our facility boasts 6000m2 of working space, where we operate 42 machines from 25 to 550 tones (Arbug, Engel, Demag, Krauss Maffei). All machines are CNC robot operated and fed automatically from a centralised drying sytem.

Plating on plastic

Our plastic plating line is a one-of-its-kind in the Balkans. We focus on producing higest quality products, facilitated by continuous improvements in our competencies, know-how, and internal processes and procedures. Plamingo's plating line is fully automated and is based on Atotech's Adhemax process, capable of putting out 1500m2 of output per day with four-minute cycles.

In-house jig construction and production

Fully automated plating system

Atotech's Adhemax process

Output of 1500m2 per day

Wastwater reatment

Four-minute cycles

We also run an in-house jig construction and production shop, where we provide value-added services to our customers, while our wastewater treatment centre ensures we minimise our effect on the environment.

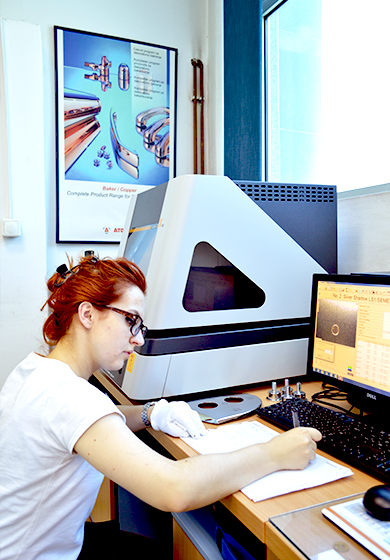

Laboratory and quality control

Our in-house laboratory, on-site of chrome plating, is capable of handling all standard testing requirements our customers need. Run by our educated, expert staff, we continuosly keep track of our production line throughout the day, making sure all relevant factors are in their optimum range and thereby reducing our scrap rate.

Residual moisture determination

Adhesion test

Cuoloscope layer thickness test

X-ray layer thickness measurement

Thermal cycle test

STEP test

CASS test

Kesternich test

Temperature shock test

NSS test

Pore counting

On the other hand, our quality control department ensures our customers get what they deserve. We run full (100%) visual control of our products continuously educating our staff on the right process. ISO9001:2015 procedures and the do's and dont's.

Value-added services

In Plamingo, we want to offer our customers a one-stop-shop solution. This means we include additional services into our mix that help our clients save time, money and energy, while minimising risk and maximising flexibility.

Tampon print

Solid Works 3D modeling

Assembly and packing

Transport

Our service mix therefore includes final marking, engraving and printing; we have our own trucks and drivers; our staff can assemble your products and pack them up; and we can help you develop your product with 3D modelling.